Five mainstream printing techniques

Five mainstream printing techniques

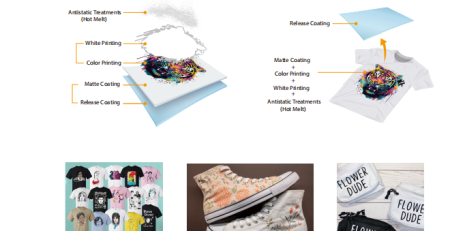

1. DTF film heat transfer process. This process is relatively simple. It can be printed through an all-in-one white ink heat transfer machine – dusting powder to fix the color – drying – winding. There is no minimum order quantity and it is very suitable for personalized customization.

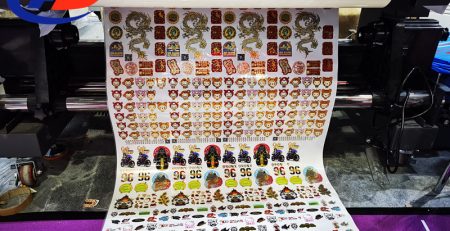

2. Offset heat transfer process. Offset heat transfer is made through four-color (CMYK) overprinting. The color effect can achieve photo effects (people, landscapes, etc.), and the color is resistant to washing and stretching. It is widely used in ready-made garments and various high-temperature resistant fabrics. Scope of use: bags, handbags, advertising shirts, cultural shirts, children’s clothing, women’s clothing, headbands, aprons, etc.

this process needs to be produced by large-scale four-color printing equipment, requires film production, and will incur printing plate charge. For large quantities, this process is more economical and affordable, and the offset heat transfer pattern has clarity and washability. better.

3. Laser engraving film process, the pattern is carved out by a cutting plotter and laser machine, and then the waste is discharged manually. The engraving film is mainly in spot color, which is suitable for monochrome effect patterns. If you need to increase the color of the pattern, you need to apply color hot stamping. Method to achieve, there are currently many types of lettering films, you can choose according to actual needs.

4. Digital direct injection process, this process is similar to a color printer. The pattern we need to print is directly printed on various materials through a digital printer, without any glue feeling. , printing is fast and convenient, no plate making is required, and single piece printing can be achieved.

5. The dye-sublimation process mainly uses heating to make the pigment molecules enter the medium. There are three ways to realize dye-sublimation: thermal-sublimation printer, dye-sublimation transfer paper, and dye-sublimation ink. The dye-sublimation technology truly achieves photo quality. A kind of printing technology: In terms of photo preservation, due to its protective layer, dye-sublimation has greater advantages than other printing technologies in terms of waterproof, UV protection and fingerprint resistance.

If you want to learn more, just contact us www dot haiyidtf dot com.

#printing#printing process#white ink heat transfer#offset heat transfer#white ink offset heat transfer#engraving film#engraving film technology#digital direct injection#sublimation#digital direct injection printing fabric#sublimation ink#sublimation printing#white ink Direct injection #laser lettering film#Strength source manufacturer