The whole process of UV DTF making?

The whole process of UV DTF

Now UV DTF becomes more and more popular in the market. But do you know how to use it?

The production process of UV DTF mainly includes the following steps:

1.Design pattern. Design the pattern that needs to be transferred to the product surface according to customer needs. This can be done using computer drawing software or by hand drawing.

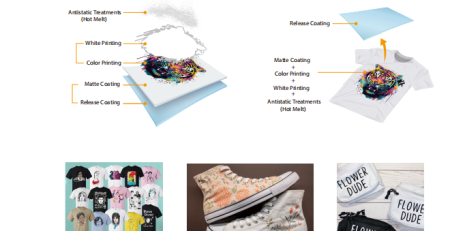

2.Print. Use a UV DTF printer to print the pattern on film A (adhesive film), while film B (transfer film) will cover the printed pattern. During the printing process, the machine can print and laminate at the same time, directly producing the finished crystal mark.

3.Crop. Cut the printed AB film according to the size of the pattern. This can be done manually using scissors, a rolling mill, or using a cutting machine, which is easier and faster.

4.Transfer. Transfer the crystal label to the surface of the product. First, peel off the back film of the crystal mark (i.e. film A), then stick film B on the surface of the product where the pattern needs to be adhered. After pressing, peel off film B, and the pattern transfer is completed.

5.Solidify. UV light is used to cure the printed pattern to ensure the scratch resistance and weather resistance of pattern.

The UV DTF has the effect of peeling off the film and leaving a pattern. In addition to the good pattern effect, it also has the advantages of scratch resistance, weather resistance, easy to stick, environmental protection, good 3D texture, waterproof and wear-resistant, bright color and wide range of use.

If you want to learn more, welcome to contact us.