Water-based DTF film, different from oil-based? Which is better?

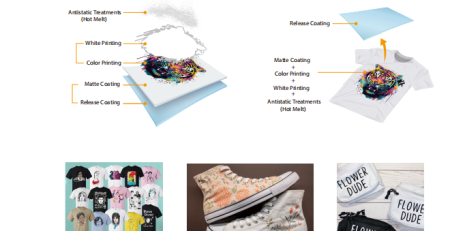

Suitable for digital transfer printing. The pattern after transfering has the same texture as PU glue, and the hand feeling softer than glue (30~50% softer than the pattern printed with oil-based coating film). Key technology – ink-absorbing release coating (3-in-1 function) can complete the three major needs of ink absorption, release, and static elimination in one process, greatly improving product quality and stability. it will save you a lot of work and trouble.

5 major advantages:

1. The pattern after transfer has a texture like PU glue, with strong stretch resilience and no deformation, and a softer feel than glue (30~50% softer than the pattern printed with oil-based coating film).

2. Adaptable to most inks on the market, it can be dispensed with 100% of the ink volume without ink accumulation or bleeding.

3. The surface of the film is dry and can be sprinkled with 200 mesh ultra-fine powder without sticking. It can be easily torn hot, warm or cold.

4. Exclusively possessing the most cutting-edge core key technologies in the industry, it has the advantage of stable quality control, and uses the power of technological innovation to lead the development of the industry in a new direction.

usage:

1. The surface with ink-absorbing coating is the printing surface;

2. Handle it with care and pay attention to the anti-scratch ink-absorbing coating;

3. Bake for 40 to 90 seconds after printing (adjust the appropriate temperature according to the performance of the hot melt powder);

4. Choose 60~80 mesh hot melt powder to achieve instant tearing, 100~150 mesh hot melt powder is recommended for warm or cold tearing, and 150 mesh or above hot melt powder is recommended for cold tearing;

5. Store in a dry place and avoid moisture.

For more info, pls contact us www dot haiyidtf dot com.