Why can not shake hot powder for DTF film clean?

1. There is a problem with the quality of DTF film. Under the same consumables and the same production environment, if you change to another DTF film and the powder sticking problem is improved, one possibility is that the DTF film is of poor quality and unqualified; the other reason is that the heat transfer film is of poor quality and unqualified; It may be that this brand of DTF is not compatible with that brand of ink. The solution is to press the ink or dtf film.

2. The ink (white ink) is too thin and contains too much water, causing the ink to flow. The oil and water of the white ink seeps beyond the edge of the pattern, causing too much hot melt powder to stick to the edge of the pattern when shaking powder, forming an obvious glue edge. You can observe if there are water stains around the pattern before the printing film is powdered, it is definitely an ink problem. Solution 1: Change the ink; Solution 2: Dry it a little before spreading the powder.

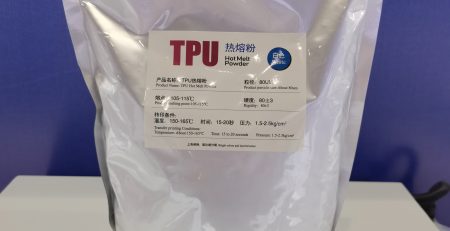

3. When the hot melt powder gets wet, it will stick to the powder and form a more obvious glue edge at the edge. Hot melt powder needs to be moisture-proof, and the damp powder needs to be baked for a while before being added to the machine.

4. White ink dries slowly. There are two situations. One situation is that some brands of ink dry slowly. The other situation is that the air humidity is too high due to the weather, causing the white ink to dry slowly. The white ink is too wet and the edges of the pattern stick to it. Excessive hot melt powder forms powder edges and glue edges. The solution is to micro-dry before applying powder. The powder shaker or printer needs a pre-drying system.

5. There is no grounding wire. Especially in winter, the dtf film has high static electricity and is easy to stick to powder. If powder sticks to the blank areas of dtf film, it may be caused by static electricity. You need to connect the ground wire. If it is grounded, If the line is still sticky in the blank area, it may be a problem with the quality of the heat transfer film. You can install an anti-static device. If the machine itself is anti-static and still has powder stuck on it, it may be a problem with the quality of the heat transfer film.

6. The quality of the powder shaker is not good and the powder shaker simply cannot be shaken clean. The solution is to replace the powder shaker.

7. The air humidity is too high and dehumidification is required.

If you want to learn more knowledge about dtf film, www dot haiyidtf dot com. Welcome to contact us.